Aqueduct history

The Dalsland Canal was completed during the years 1864-1868. The work was led by the well-known canal builder Nils Ericson. Depending on the soil conditions in Håverud, it was not possible to build a regular sluice plant there. The rocks were loose, the stream strong and the cliff too steep. Nils Ericson came up with the brilliant idea to build an aqueduct instead.

The history of the aqueduct

The Dalsland Canal was completed during the years 1864-1868. The work was led by the well-known canal builder Nils Ericson. Depending on the soil conditions in Håverud, it was not possible to build a regular sluice plant there. The rocks were loose, the stream strong and the cliff too steep. Nils Ericson came up with the brilliant idea to build an aqueduct instead. His son, Werner Ericson became site manager.

The aqueduct was manufactured by the famous company Bergsund's Mechanical Workshop in Stockholm. The plates were assembled ashore and the heavy gutter was then slid into place over the rapids.

The aqueduct is a freely hanging bridge, where the water is led into a 33.5 meter long sheet trench above the rapids. The plates are joined with 33000 rivets.

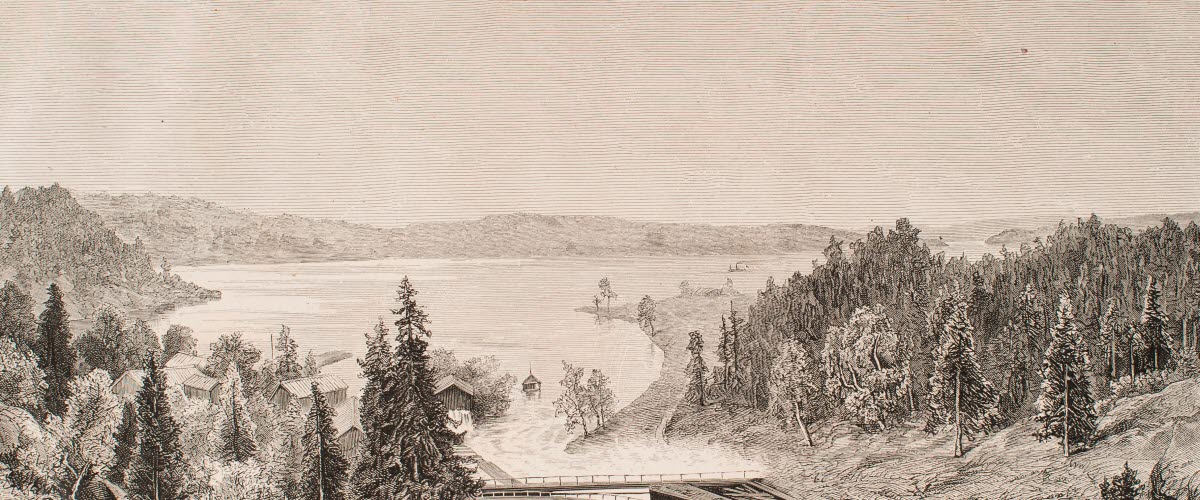

When building the Dalsland Canal, Håverud was the point on the sailing route that was the biggest obstacle to an unbroken waterway. Here was a ravine surrounded by high mountainous beaches. Through this narrow valley with cross steep sides, a gate was formed, through which the Håveruds stream overflows, carrying out a near nine meter fall which opens into the lake Upperudhöljen.

Establishing a canal here in the stream, between the high rock walls, the squeezed in stream, was naturally associated with significant costs and technical difficulties. Therefore, in his proposal, Major Liliehöök had recommended a railway over Håverudsedet instead of a canal.

There was really only one satisfactory solution to the problem: to get a sail past Håverudsfallet, and this was to somehow get the canal across the falls. Colonel Nils Ericson then proposed an iron plate aqueduct.

Design

The aqueduct's construction is in the form of a box open at both ends. The side pieces, in which the carrying force is extended, are arcuate at the top so that the height of the middle is 10 feet, about 3 meters and at the ends 6.5 feet, about 2 meters. Both sides and bottom are of ¼ inch, 6 mm English plate Foot and top flanges are of ½-5/8 inch, 12.5-15.5 mm plate - simple at the ends and in the middle increased to threefold. The top flanges also serve as a footbridge or drawbar with a railing at the outer edges.

To reinforce and make the structure stiffer, a "skeleton" of iron reinforcements is placed exterior to the sides and bottom, consisting of two different designed systems that alternate with each other. One consists of an angle iron below the base, to which a reinforcement of flat iron, in the form of a reverse suspension, is attached, and another angle iron fixed to the outside of each side piece, middle above the first, bent in the top and foot flange, and in the angle against the latter reinforced with a triangular filling plate. This type of reinforcement is placed along the entire length of the aqueduct with three feet, about 0.9 meters, apart. Every fifth of them is replaced with reinforcements of the second structure, which have angular iron throughout the bottom and on the sides equal to the former, but the reverse suspension under the bottom is replaced with a plate riveted to the angle iron and on the sides also plates are riveted to the angle iron. These filler plates are reinforced with one, round the sides and bottom, running angular riveted to the outer edge, and another running under the bottom and past the angles and applied on the other side plate opposite the former.

Reinforcements of this type are used at 15 feet, about 4.5 meters, at intervals. Under all the bottom reinforcements, two flat bars run parallel to the longitudinal direction to establish the vertical position. At both ends of the Aqueduct, the sides are further reinforced by densely placed vertical fixed angles. Inside the aqueduct at level with the water surface runs a wooden railing that serves as a carrier.

At both ends, the aqueduct is connected to the masonry erected there. The dilatation (enlargement / contraction) whose common influence on ordinary bridges is easily prevented by moving rest, here also leads to the inconvenience that the seal between the iron and the masonry must also be made movable. This is accomplished as follows: At the eastern end, where the aqueduct bumps into the brick pillar in front of the recess in lock # 6, two vertical oak beams are bolted to the wall, and a horizontal oak beam is recessed and bolted to the landing wall's pallet wall. Between the beams and the walls is a thick wadding insert. The beams are hollowed out so that the side plates are inserted in the vertical beams and an angle iron fixed below the bottom plate, in the horizontal beam. The opening in the vertical beams is closed with a leather strap, which with one edge is fastened along the beam and with its other can clamp close to the side plate through the screwed wooden strip.

The opening along the horizontal beam only needs to be filled with sawdust behind which a small drive is plugged. A lid of iron plate prevents the sawdust from being flushed away. The rollers under the bottom flanges of the sides are those which are commonly found at iron bridges. The base plate is supported by three up and down rails, riveted to the plate and running on small rollers, two under each rail piece, fixed in storage chairs.

The aqueduct's western end rests unobtrusively on the landing bracket, so variable sealing need not be applied. The transition from the iron to the masonry is also mediated here through oak beams, where the plate is simply nailed.

The aqueduct can be filled to 5.5 feet, 1.6 meters, water depth and is then loaded with about 5,580 centers, 237,150 kg. Added to its own weight, 1,500 cents, 63,750 kg, the design has to carry an evenly distributed load of 7,080 cents, 300,900 kg.

The aqueduct has been manufactured by Bergsunds Mekaniska Verkstad (Bergsund's Mechanical Workshop), Stockholm, in terms of both detail design and workmanship.

Location on site

The foundations for the land mounts are simple, as the walls could be set directly on rocks. At the eastern end, pallet walls were raised and opened directly on the rock. At the western end, a smaller rock existing under the water surface of the stream was used as the basis for the land attachment. It became easy to access, when there was an opportunity to have the water surface lowered, just as much as needed, by keeping the mill's dust hatches open, while the foundations for the land mooring and other masonry in the vicinity were in progress.

For the aqueduct overhaul, less elaborate facilities were needed than one might expect. As both the depth and the strong current in the river impeded the obstacle to the application of any support between the land mounts, the aqueduct must be assembled ashore and then slid into place. A projecting rocky slope on the eastern side of the stream, opposite to the west shore, came in handy. On this was erected by pile timber a makeshift landing bracket, which extended into the stream so far that the distance from the same to the western land bracket of the aqueduct was only 50 feet, about 15 meters.

The aqueduct was now accumulated, resting on eight-inch round-planed timber, which rolls extended throughout its width. The rolls went on five rows of long sticks, which were lying on strung lid. The reinforcement skeleton under the bottom, which would be in the way, was not applied until the aqueduct became overheated and the vertical position of the sides was maintained during the time by stays applied inside the aqueduct. The space inside the west shore did not allow more than half the length to be assembled at one time. Therefore, the eastern half of the aqueduct was first cobbled together and was cut out and sheared in several stages, until the end reached the opposite shore. Two Betancourt games were enough for this strong for this slant. The heaviest work was left to get it in place. Explosions created space for a rolling plane, which was formed by cross-laid beams, like a regular window pane. In order to achieve at the same time a twist and a forward movement on the aqueduct, the rollers on this roller plane were placed obliquely under the ends of the aqueduct or approximately perpendicular to the path that it should follow. Two six-plate waists along with the games were needed for this slant. After reaching about midway, the Aqueduct was first assembled to its entire length and pulled into place.